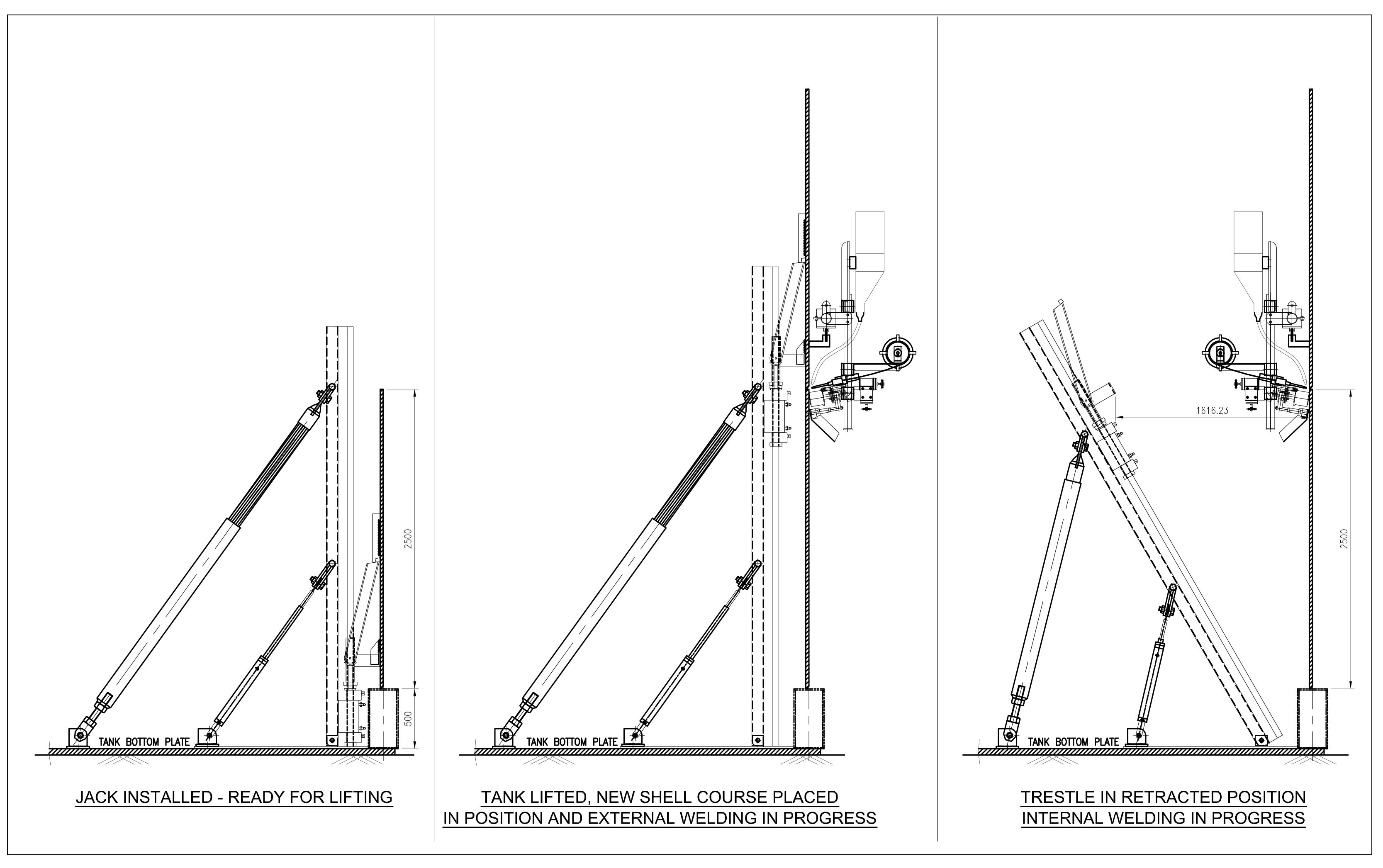

Retractable Jacks

Once the tank is lifted using our jacking equipment, and a new course (shell ring) is placed, vertical welds are completed either manually or using an automatic FCAW welding machine. Thereafter, external horizontal welds are done using our SAW single side Automatic Girth Welding machine (Root weld can be done either manually or using a feaw attachment of our Automatic Girth Welding head with the additional use of a ceramic backing strip).

After external welding, the tank load is released from jacks, lifting lugs and fend-off lugs are cut-off, and with the push of the operating lever on the same powerpack (which is used for lifting jacks), all trestles retract away from the tank shell, to allow for space for the use of the Bygging SAW single side AGW for internal welds.

This allows optimum utilization of the AGW and considerably reduces the need to employ manual welders, which would otherwise be required for internal welds.

Once internal horizontal weld is completed, the jack trestles are moved back hydraulically all at once to their original vertical position, ready to lift the next shell course (Patent applied)